So far this semester has been fairly productive for the Active Suspension Team. We have made solid headway in the recent weeks by acquiring most of our needed materials as well as various components. Being the "controls guy" I experienced some difficulty when researching which actuators and various sensors our team would need. The idea was to balance cost and effectiveness when determining which components we would purchase. With so many parts to choose from, but only a few being good candidates, it took some time to track down exactly what we would need.

Nonetheless, we have now purchased actuators, I have determined which motor driver we will need for the best available price, and we have made a decision on what sensors we will need to properly control the active suspension. Our team is nearly finished with the fabrication portion of our design process, with the next step being integrating the control system and troubleshooting for flaws. We expect to have plenty of time to have our system up and running, with time to spare.

Finally, due to the fact that our team is on track, there have been times when I had nothing to do or was waiting for one step to be complete before moving forward. In order to help the entire Spartan Superway Team reach its goal, I have decided to help out Alex (Guideway Team) with some fabrication and/or anything else he wants help with. He is working on a critical piece of our project and without he completion of the guideway our presentation at Maker Faire will be a loss. I also figure this will help me stay more connected with the project as a whole and help to build stronger teamwork.

Spartan Superway 2015-2016

Sunday, March 20, 2016

Wednesday, November 18, 2015

Update 11/18

Since my last update I have done more research on different types of actuators and their trade-offs. For our system we would like to use the most efficient components in terms of power output, weight, and power requirement.

Ball screw type actuators have less internal resistance due to friction and offer a greater performance for a given power input. However due to the construction, this reduced friction can allow for "back-driving". This simply means that the external force acting on the end of the actuators rod can cause the motor to turn, and would be a problem for our suspension design.

Ball screw type actuators have less internal resistance due to friction and offer a greater performance for a given power input. However due to the construction, this reduced friction can allow for "back-driving". This simply means that the external force acting on the end of the actuators rod can cause the motor to turn, and would be a problem for our suspension design.

Ball Screw Drive

Our suspension design is predicated on the ability of the actuators to be able to control the angle of the cabin with respect to the ground, as well as support the weight of the cabin and its occupants. Therefor back driving of the actuators due to the load of the cabin could be potentially dangerous, and could occur unexpectedly with the wrong actuators installed.

To reduce the possibility of backdriving, the use of Acme screw type actuators may be a better solution. They are not as efficient as Ball Screw driven actuators, but they almost eliminate the chance of being backdriven. With safety a paramount concern in this project, it makes more sense to sacrifice some efficiency for safety. Additionally, Acme Screw driven actuators are often cheaper to produce than Ball Screw actuators, which would help minimize our overall expenditures.

Acme Lead Screw

In addition to actuator sizing, the type of actuator used is one more factor we need to consider. Our group has come up the geometric design of the suspension system. At this stage we just need to make the final decision on what shocks and actuators will best suit our needs.

Wednesday, October 7, 2015

Update: 10-7

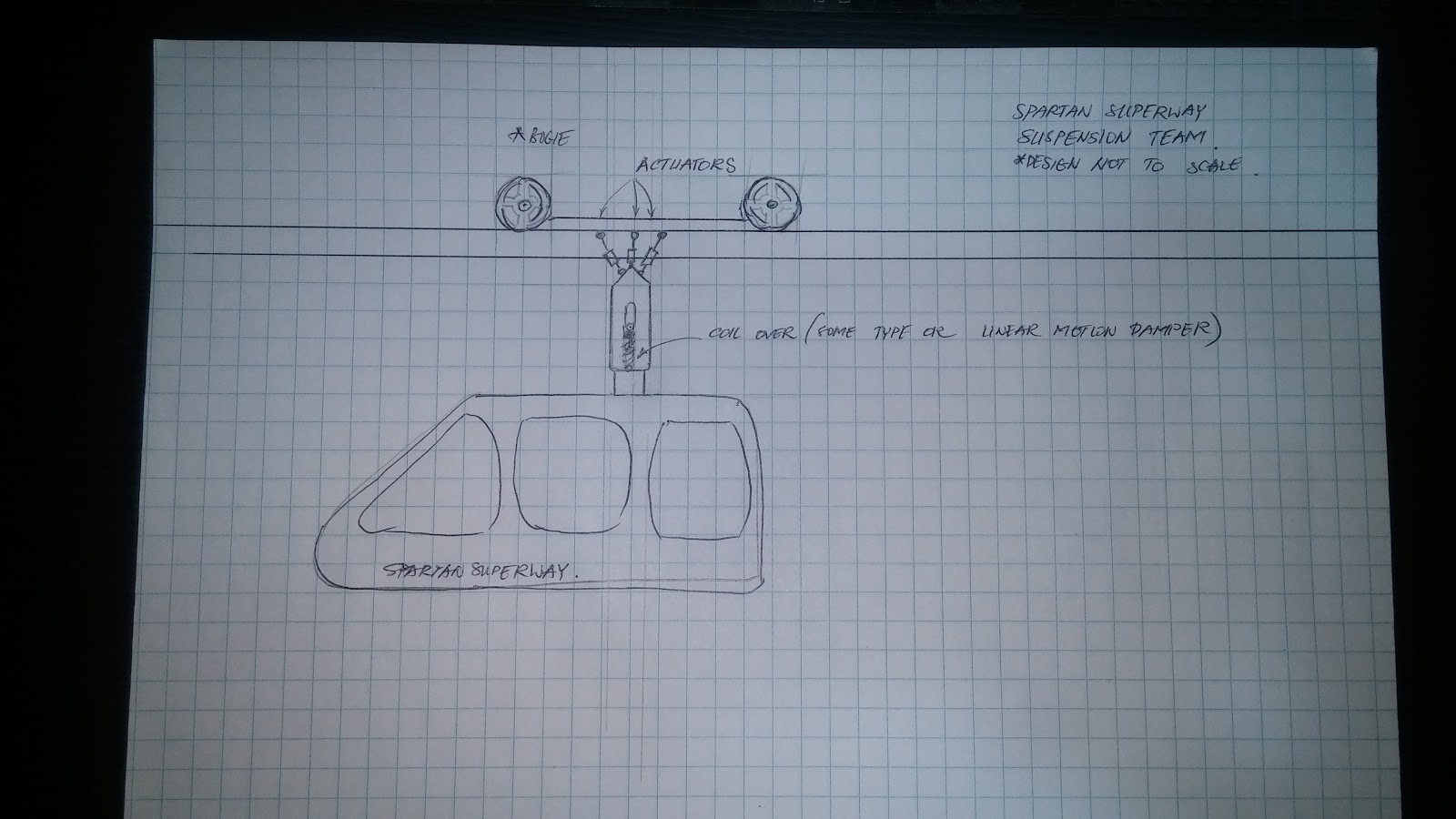

Last week our team presented our idea for an active suspension design. The design consists of 2 coilover shocks mounted to the top of the cabin running to a rectangular slider. Due to the geometry of the rectangle slider, it will only allow vertical displacement, and limit any twisting. The way the slider works is there is a male piece of rectangular tubing mounted to the cabin tat slides inside of a female piece that is mounted underneath the bogie. There will be channels in the sides on the female tube to guide the shocks through their travel.

As of right now, we have only briefly discussed how friction will be taken care of. I mentioned using Teflon pads inside the slider to minimize friction between the two sliding tubes, with integrated grease fittings/nipples. I think this is a good idea, but I am skeptical as how it would hold up over time. Also, the channels for the shock pins will need sort of bearing in order to minimize friction and reduce wear.

Tyler made this CAD of the slider with coilovers based on what are group had sketched up by hand. After looking at it, I think it has potential but needs some critical improvements. The pins that support the shocks, and subsequently the entire cabin are in single shear, and would likely have a high fatigue rate if mounted in this way. At the very least, we need to come up with a way to put these connections in double shear, for safety and longevity. Also, for the channels, it would be good to have a means of closing off the sections around the pins with some sort of move-able seal, so that debris does not enter the slider causing increased wear on the slider.

Now that our team has decided on a suspension configuration, we can now begin to look into what components will be needed to make this system work. I began to focus this week on the active part of the suspension, namely the actuators. For our 1/4 scale model I made a conservative estimate of 500lbs for the weight of the cabin and its occupants (2,000lbs full scale).

The way we have isolated the suspension from the cabin control system means the actuators must support the full weight of everything beneath the bogie. The plan is is use 3 actuators in total, 2 of which will be used to control the angle, and all 3 will contribute to the leveling of the cabin as it approaches the loading platform. With this design, the actuators are a critical safety component, as they will be under constant load, with frequent impulses. This is concerning because the entire safety of the system is predicated on the quality of the actuators. That said, with the right actuators the shouldn't be a problem.

However, with a limited budget, it may be difficult to find the perfect actuators for our needs. In theory, each actuator only needs to support about 1/3 of the load, but when a factor of safety is included, this number will likely increase significantly. After some research, I have found actuators that can support loads close to what we need, the problem is the size. For example, I found actuators that can support 400lbs, but are far too large for our application.

I think with more research I should be able to find something that fits our needs, though it will be a challenge to balance loading, size, weight, and cost.

Here is a link to some promising options: https://www.firgelliauto.com/products/heavy-duty

As of right now, we have only briefly discussed how friction will be taken care of. I mentioned using Teflon pads inside the slider to minimize friction between the two sliding tubes, with integrated grease fittings/nipples. I think this is a good idea, but I am skeptical as how it would hold up over time. Also, the channels for the shock pins will need sort of bearing in order to minimize friction and reduce wear.

Tyler made this CAD of the slider with coilovers based on what are group had sketched up by hand. After looking at it, I think it has potential but needs some critical improvements. The pins that support the shocks, and subsequently the entire cabin are in single shear, and would likely have a high fatigue rate if mounted in this way. At the very least, we need to come up with a way to put these connections in double shear, for safety and longevity. Also, for the channels, it would be good to have a means of closing off the sections around the pins with some sort of move-able seal, so that debris does not enter the slider causing increased wear on the slider.

Now that our team has decided on a suspension configuration, we can now begin to look into what components will be needed to make this system work. I began to focus this week on the active part of the suspension, namely the actuators. For our 1/4 scale model I made a conservative estimate of 500lbs for the weight of the cabin and its occupants (2,000lbs full scale).

The way we have isolated the suspension from the cabin control system means the actuators must support the full weight of everything beneath the bogie. The plan is is use 3 actuators in total, 2 of which will be used to control the angle, and all 3 will contribute to the leveling of the cabin as it approaches the loading platform. With this design, the actuators are a critical safety component, as they will be under constant load, with frequent impulses. This is concerning because the entire safety of the system is predicated on the quality of the actuators. That said, with the right actuators the shouldn't be a problem.

However, with a limited budget, it may be difficult to find the perfect actuators for our needs. In theory, each actuator only needs to support about 1/3 of the load, but when a factor of safety is included, this number will likely increase significantly. After some research, I have found actuators that can support loads close to what we need, the problem is the size. For example, I found actuators that can support 400lbs, but are far too large for our application.

I think with more research I should be able to find something that fits our needs, though it will be a challenge to balance loading, size, weight, and cost.

Here is a link to some promising options: https://www.firgelliauto.com/products/heavy-duty

Monday, September 21, 2015

9/21/2015

Last Wednesday (9/16) our group met during class and shared our ideas for the suspension design. We all tried to come up with our own take on how the suspension might work. Everyone had one or two different sketches , some were similar and others were completely thinking outside the box. We then discussed the pros and cons of each design. No signal design seemed to be perfect, yet each one had some positive aspects that could be incorporated into the final design. I think seeing everyone else's designs helped to spark ideas in the group and make each of us think about the problem in a different way. We all liked the idea of using the best parts of each design to come up with a comprehensive design that satisfies all of the requirements per the project scope.

Since last week, I have worked on revising my previous sketch and doing a bit more research on the particular suspension concept that I have been working on. I have been playing with the idea of using a cantilever style suspension, mainly because it has the potential to be packaged tightly above the cabin without sacrificing performance. I suspect that space will be at a premium with the entire Superway project, so being mindful about this possible restriction when designing seems like a good approach to me. With a cantilever suspension, there is a common fixed pivot point about which the cantilever arm rotates, however the distances from the dampers to the pivot and the cabin to the pivot need not be the same. Actually, it could be beneficial to design a 2:1 (or some other desirable ratio) cabin to shock displacement cantilever arm. Meaning, the damper moves 1 unit for ever 2 units of cabin displacement. With a design like this, a smaller damper (maybe a coil-over shock) can be used, which helps to keep the design more compact.

The last sketch I made had the fixed pivot and and push rod and an additional damper mounted to the top of the cabin. I eliminated the extra cabin mounted damper and moved it to the underside of the bogie. Also, I sort of inverted the orientation of the cantilever arm, this just seemed to look like a better setup. Instead of having two center mounted, side by side cantilever systems, I put them in-line front to back which seems like it may be more stable.

The major change I made, which was sparked by my group members' sketches, was to mount the suspension in-between the cabin and a platform, with actuators between the platform and the bogie. Now the entire actuator system and suspension system are isolated from each other. The actuator system is used to control the angle of the cabin with respect to ground when ascending and descending. The benefit of keeping these two systems separate is that the angle of the cabin can be changed without changing the geometry of the suspension system. The entire system would be supported by one or two pinned linkages, the angle of which would be controlled by the actuators.

Since last week, I have worked on revising my previous sketch and doing a bit more research on the particular suspension concept that I have been working on. I have been playing with the idea of using a cantilever style suspension, mainly because it has the potential to be packaged tightly above the cabin without sacrificing performance. I suspect that space will be at a premium with the entire Superway project, so being mindful about this possible restriction when designing seems like a good approach to me. With a cantilever suspension, there is a common fixed pivot point about which the cantilever arm rotates, however the distances from the dampers to the pivot and the cabin to the pivot need not be the same. Actually, it could be beneficial to design a 2:1 (or some other desirable ratio) cabin to shock displacement cantilever arm. Meaning, the damper moves 1 unit for ever 2 units of cabin displacement. With a design like this, a smaller damper (maybe a coil-over shock) can be used, which helps to keep the design more compact.

The last sketch I made had the fixed pivot and and push rod and an additional damper mounted to the top of the cabin. I eliminated the extra cabin mounted damper and moved it to the underside of the bogie. Also, I sort of inverted the orientation of the cantilever arm, this just seemed to look like a better setup. Instead of having two center mounted, side by side cantilever systems, I put them in-line front to back which seems like it may be more stable.

The major change I made, which was sparked by my group members' sketches, was to mount the suspension in-between the cabin and a platform, with actuators between the platform and the bogie. Now the entire actuator system and suspension system are isolated from each other. The actuator system is used to control the angle of the cabin with respect to ground when ascending and descending. The benefit of keeping these two systems separate is that the angle of the cabin can be changed without changing the geometry of the suspension system. The entire system would be supported by one or two pinned linkages, the angle of which would be controlled by the actuators.

Monday, September 14, 2015

Active Suspension Ideas: Cantilever Sketch

One idea that I had last week for the active suspension was to implement a cantilever type suspension system. This is an appealing option be cause of the variety of different ways a cantilever suspension can be designed. Considering the Spartan Superway as a whole, designing each component with efficiency in mind is crucial. The idea is to mount a spring and shock (coilover) in a horizontal orientation creating a compact system, still allowing the damper to operate in compression.

This preliminary sketch shows the principle of a cantilever suspension system, and could obviously be designed to be much more compact and refined (this is side view, imagine another set of shocks and cantilever behind/into the page). One of the criteria for the active suspension is the ability to maintain a level position on a 17 degree slope. This requirement could be fulfilled using an actuator mounted vertically at the end of the cantilever arm. When the bogie and cabin begin to descend down the slope, the actuator will extend, keeping the cabin in a horizontal plane. The actuator would retract when the bogie begins to ascend back up the track.

While this system has a lot of versatility, it also is a bit more complicated and unorthodox compared to just mounting dampers vertically above the cabin. One thing that would need to be incorporated into this design is a method of controlling the ride height when the cabin arrives at the platform and passengers load/unload. This could possibly be accomplished by the actuator mounted as shown, but some 3D motion analysis would be needed to really understand how this system would behave. Another idea that I had (not shown in sketch) was to incorporate a sway-bar across the two cantilever arms to limit the roll of the cabin around turns.

I still need to run this sketch by my group members and get their input. We had discussed some other suspension ideas that were simple and to the point, but may lack some refinement and adaptability. This cantilever approach definitely is not the most straight forward, but with some brainstorming and refinement, it may offer the best active control of the cabin's movement.

Wednesday, September 9, 2015

Active Suspension Ideas

Requirements

The suspension requirements for this project have to potential to be fairly complicated. Fundamentally it will do what any other suspension does; stabilize and support the vehicle while maintaining an adequate level of comfort for its occupants. However, with the bogie and cabin hanging below its support, we will need to design a way to convert the tensile loading into a compressive load for the suspension components. This isn't 100% necessary, but in my experience suspensions are generally designed to operate in compression and rebound in tension. Therefore, if we were to use "off-the-shelf" parts in our prototype, it makes more sense to design a suspension that is capable of using readily available parts rather than something unproven or with little known characteristics.

There are a number of areas that we need to focus on and address in terms of what motions are desired from this suspension:

Basic Travel Around The Track

-Vertical Stability: keep the cabin from oscillating up and down over uneven parts of track and through transitions.

-Horizontal Stability: keep the cabin level to the ground when negotiating turns to avoid a "pendulum effect".

Arrivals and Departures

If some of the stations are to built at street level (which seems practical) then the cabin/bogie will need to ascend/descend to pick up passengers. With the track sloping to and from street level, we will need to design a way to "self-level" the cabin/bogie with respect to round so that the passengers do not experience a huge change in angle(pitch) as the bogie leaves each station.

In addition to the leveling of the cabin, our team discussed that full cabin will obviously weigh more than an empty one. When the cabin arrives at the station, it should maintain a certain height in relation to the platform passengers load and unload from, especially for safety reasons. To accomplish this, we will need to design a way to adjust the "height" of the cabin under various loading conditions, while still maintaining functionality in the other situations.

Where to Start?

This will no doubt be a challenge to incorporate all of these features into a cohesive suspension system that works in unison with a variety of sensors to monitor and control the position of the cabin.

I think a good way to start designing would be to generate the specific motion and mechanics required. Once we are confident and satisfied with the basic functionality, we can then figure out how to integrate controls in the system.

I read a bit from my teammate Scott's blog post on a suspension idea utilizing a cantilever system. I too had thought about such a route when I was brainstorming. There may be some potential for this type of a configuration. The way a cantilever suspension works is through the use of a push-rod, and a pivot arm (cantilever) where the push-rod and spring/shock are attached. This can be designed as a very compact system, where the spring and shock actually operate perpendicular to the motion of the vehicles oscillation. This is no doubt a unorthodox method, but it can be extremely versatile and has the advantage of being compact due to the fact that there is a ratio involved with the amount of travel by the vehicle, and the suspension components. A traditional suspension is setup in parallel to the motion of the oscillation, so if the cabin where to move 6", the springs would move 6" (if there is no spring/shock angle). With a cantilever system, a mechanical ratio is induced due to the pivot arm and push-rod dimensions, meaning, depending on the design, a 2:1 or 3:1 ratio of cabin to shock movement could be implemented; lending to a very compact suspension system.

This explanation is probably a bit hazy if you have never seen a cantilever suspension before, so here is a picture to give you a better idea of what it might look like:

I read a bit from my teammate Scott's blog post on a suspension idea utilizing a cantilever system. I too had thought about such a route when I was brainstorming. There may be some potential for this type of a configuration. The way a cantilever suspension works is through the use of a push-rod, and a pivot arm (cantilever) where the push-rod and spring/shock are attached. This can be designed as a very compact system, where the spring and shock actually operate perpendicular to the motion of the vehicles oscillation. This is no doubt a unorthodox method, but it can be extremely versatile and has the advantage of being compact due to the fact that there is a ratio involved with the amount of travel by the vehicle, and the suspension components. A traditional suspension is setup in parallel to the motion of the oscillation, so if the cabin where to move 6", the springs would move 6" (if there is no spring/shock angle). With a cantilever system, a mechanical ratio is induced due to the pivot arm and push-rod dimensions, meaning, depending on the design, a 2:1 or 3:1 ratio of cabin to shock movement could be implemented; lending to a very compact suspension system.

This explanation is probably a bit hazy if you have never seen a cantilever suspension before, so here is a picture to give you a better idea of what it might look like:

This is meant to be used on an offroad vehicle, but the concept is the same. The lower horizontal tube represents the axle that travels vertically up and down. The shocks are then actuated via a pushrod (lower vertical shorts arms mounted between axle and cantilever arm) and the cantilever arm that rotates about a fixed point. There are many ways to modify this design, this is just an example of the concept.

Meeting-Weds Sept. 2nd

This was our first official meeting at the Spartan Superway project warehouse (between 3rd and 4th and St. John st) where everyone had a chance to see the current state of the prototypes. At the beginning of the meeting we went through the introductions of all of the instructors and mentors who will be guiding and supporting us throughout the next school year. The previous week each of the new team members/students (myself included) were tasked with doing a bit of research to familiarize themselves with the project; what has been done, what worked and what didn't work, and what needs to be done in the future to make Sparta Superway into a reality. For this meeting each of the team members gave a brief speech on some of their findings on the Spartan Superway, focusing on a particular area of interest. This not only gave everyone a more insight on the project as a whole, but allowed each of us to get a better idea of who we might be working with based on a common area of interest between different group members. With a group as large as this, where many of us haven't had the chance to meet each other, this was a great way to "speed-date" and figure out who would group together into the various sub-teams.

Once we finished all of the presentations, we toured the facility and familiarized ourselves with the work space and all of the current prototypes. After we got a good look at the shop, we broke into the various sub teams. I chose to work on the Full Scale model, more specifically the Active Suspension group. As of now, our members include Scott, Dale, and NJ for a total of 4 members. I was a bit surprised to only have 4 people take interest in this sub-team, as many expressed interest in the active suspension during presentations. However, this makes for a few less "moving parts" when it comes to meeting up and working together.

Currently, the suspension design for the cabin has some design flaws, and will need to be modified if not completely redesigned for this years goals of an active suspension. There are some ideas in place on how the cabin should behave when loading/unloading, as well as running up and down the track from station to station. however, unlike some of the other aspects of the project, there aren't any concepts from previous years' work on how the active suspension should be designed. This leaves the door wide open to new ideas that our team will need to collaborate on. Now that each of us have gotten to know each other and we can begin to find our individual roles within our team and start the design process that will challenging yet rewarding!

Once we finished all of the presentations, we toured the facility and familiarized ourselves with the work space and all of the current prototypes. After we got a good look at the shop, we broke into the various sub teams. I chose to work on the Full Scale model, more specifically the Active Suspension group. As of now, our members include Scott, Dale, and NJ for a total of 4 members. I was a bit surprised to only have 4 people take interest in this sub-team, as many expressed interest in the active suspension during presentations. However, this makes for a few less "moving parts" when it comes to meeting up and working together.

Currently, the suspension design for the cabin has some design flaws, and will need to be modified if not completely redesigned for this years goals of an active suspension. There are some ideas in place on how the cabin should behave when loading/unloading, as well as running up and down the track from station to station. however, unlike some of the other aspects of the project, there aren't any concepts from previous years' work on how the active suspension should be designed. This leaves the door wide open to new ideas that our team will need to collaborate on. Now that each of us have gotten to know each other and we can begin to find our individual roles within our team and start the design process that will challenging yet rewarding!

Subscribe to:

Comments (Atom)